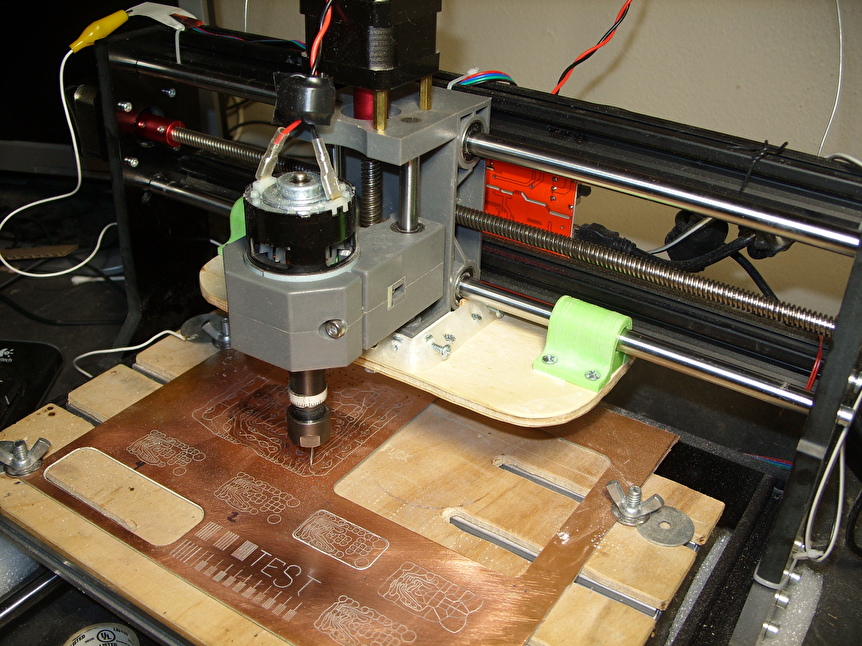

I built this stabilization thing for the CNC machine. It's the piece of plywood that has some green 3D printed plastic bolted onto it, and then in the middle it attaches to the X axis carriage with some other bolts that clamp onto it when tightened.

This came about because I noticed that the spindle could be deflected left and right quite a bit, and traced this back to the linear slide bearings on this thing being rather loose. I'm not surprised, as the ones on my 3D printer are kind of loose too, and I question how the things even work on the inside since normally bearings roll but in a linear bearing there's nowhere for them to roll to. So what's holding them in place and why don't they wear into it?

IDK, but I also knew that they weren't necessary because on my 3D printer I'd replaced the X axis linear bearings with 3D printed things that simply bolt around the slide rails and never had a problem with that replacement.

So I decided to do the same thing here. The bottom is just a piece of plywood. The linear "bearings" are just a small ring of ABS plastic that fits inside the larger green piece which is PLA. I did this because ABS seems to have less friction, but PLA is easier to print, and I didn't want to re-print the green part a dozen times trying to get the best fit, whereas reprinting that tiny piece of ABS would be no big deal. I ended up just printing them too small and sanding them to fit the bar perfectly. I also made the clear plastic part that attaches to the gray X axis carriage a very loose fit and designed bolts and nuts to go around it and clamp into it, to firmly attach it to the plywood.

The original bearings are quite loose. With the slide rail installed, it can wiggle back and forth about 5 mm at the ends. However, the one that goes through my new attachment doesn't want to wiggle at all.

I haven't done much to test this yet, other than carve some text into the PCB, which I noticed has thinner vertical lines than horizontal ones. I can only guess that's because it doesn't vibrate as much horizontally now.

This removes about half of the horizontal movement range, but since I'm only using it for PCBs, I don't really care. I can just put them in the middle.