Indeed, my code to adjust the Z height to match the height of the copper had a bug, causing it to work incorrectly if the XY zero point of the PCB I was making wasn't the same as where the machine was when it was turned on. So I fixed that.

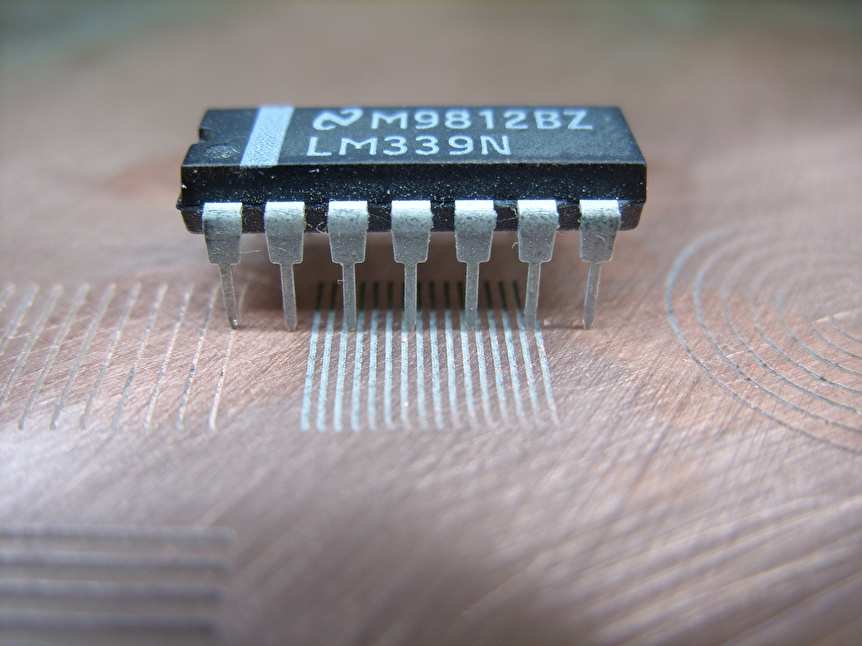

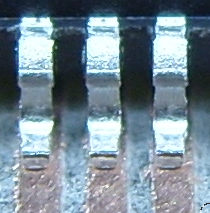

I then wondered if I wasn't using the broken carving bit. So I pulled it out and compared it to another, and really couldn't tell the difference. So I put in a different one, made some test cuts, and it looked about the same. So I put in yet another carving bit and tried again, at which point I got this insanely accurate result:

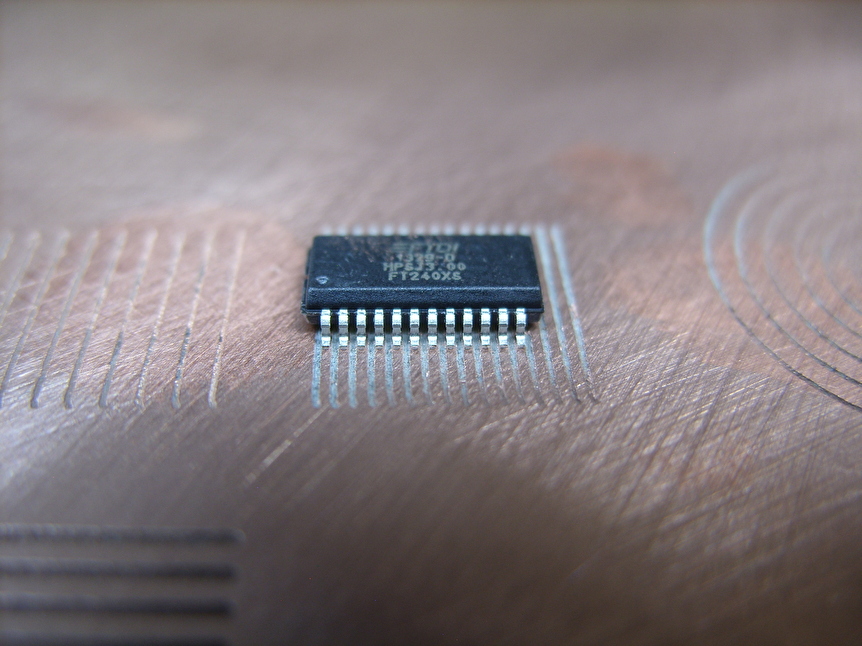

That looked good enough to do surface mount, so I tried carving some lines at 0.025 inch spacing, and got this:

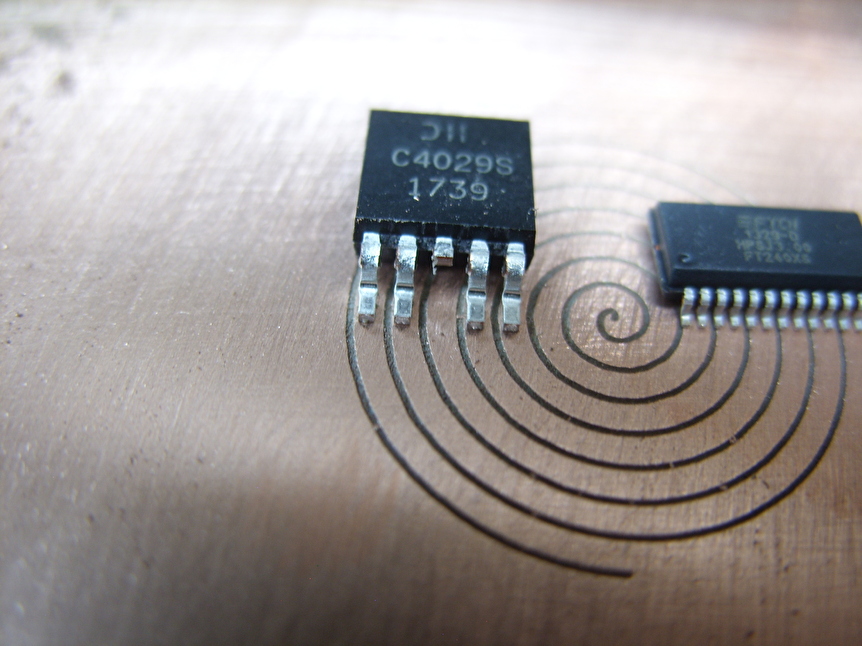

...and here that is next to a normal IC in case anyone doesn't know how stupidly tiny the FT240X is.

So maybe I just need better carving bits. I'm just using the ones that came with the machine.

I also noticed there's quite a bit of play in the spindle mount, seemingly because the slide bearings don't hold it in position all that well. So I was thinking the problem might be with that, but after seeing the 0.025 inch cuts above, that apparently doesn't matter too much.

I'm really amazed by this. Measuring the pixels, it looks like it cut out 40% of the 0.025 inch spacing, making the width of the cuts 0.01 inch or 0.254 mm.